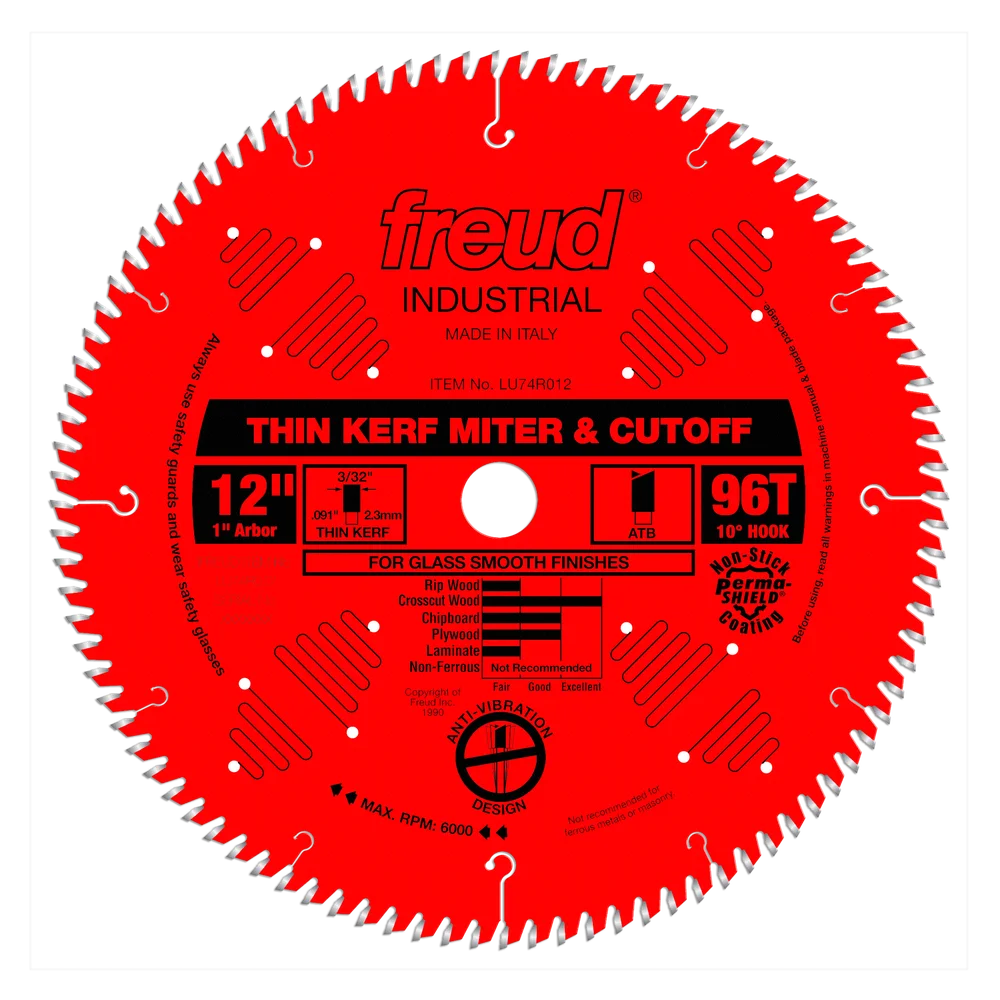

FREUD LU74R012 12" THIN KERF CUT OFF BLADE

FREUD LU74R012 12" THIN KERF CUT OFF BLADE is backordered and will ship as soon as it is back in stock.

Usually in stock, ships within 3–5 business days.

Couldn't load pickup availability

Delivery and Shipping

Delivery and Shipping

We will ship your order out as soon as we can. If your order is placed after hours it will be fulfilled the next working day. If an item of your order is out of stock, you will be notified via email, as well as the possibility of partially shipping your order. For any questions and concerns please don't hesitate to give us a call.

Description

Description

FEATURES:

- Freud’s exclusive blend of TiCo™ Hi-Density Carbide is specifically designed for each cutting application to maximize cutting life and material finish

- Freud’s own Silver I.C.E. Coating™ reduces heat, build up, and eliminates rust and corrosion to maximize the life of the blade

- Hi-Alternate Top Bevel (Hi-ATB) tooth geometry with Axial Shear Face side grind polishes the material to produce a superior finish in high-speed applications

- Thin kerf blades remove less material than standard carbide blades, thus requiring less horsepower to produce equally good results

- Laser-cut blade body with anti-vibration technology add superior stability, a precise quality of cut while reducing machine vibration and maximizing the life of the blade in upcut saws and large production manufacturing

- Tri-Metal Brazing gives the tooth superior bond strength and protects the carbide tooth by giving it increased flexibility and impact resistance

- Freud’s Hi-Tolerance Precision Plate Grinding & Tensioning features a laser cut blade body from 48 Rockwell steel plate (the world’s highest quality steel) that remains flat and true, over the lifetime of the blade for ultimate accuracy

- Resharpenable at any Freud Authorized Service Center